John Deere sprayer with AutoTrac RowSense

John Deere sprayer with AutoTrac RowSense

Hagie™ sprayer with AutoTrac RowSense

Hagie™ sprayer with AutoTrac RowSense

RowSense paddle, sensor, and bracket

RowSense paddle, sensor, and bracket

AutoTrac RowSense system allows sprayer operators to experience the benefits of AutoTrac while spraying in standing corn rows. The system provides additional input to the AutoTrac system to ensure that the sprayer is accurately following the planted crop rows. By utilizing RowSense, operators can experience reduced crop damage, faster operating speeds, and reduced operator fatigue.

AutoTrac RowSense has been shown to perform well in straight rows whenever the sensor contacts the corn plant on the stalk, rather than the leafy part of the plant. This generally occurs at a plant height of around 1.2 m (4 ft) with many varieties. If a row guidance solution is desired in early crop stages, be sure to check out AutoTrac Vision in the Sales Manual.

The system is compatible with select John Deere and Hagie sprayers.

- For compatible John Deere sprayers, RowSense works in straight corn rows with 50.8 to 101.6-cm (20 to 40-in.) row spacing and has been tested at speeds up to 32.2 km/h (20 mph).

- For compatible Hagie sprayers, RowSense works in straight corn rows with 76.2-cm (30-in.) row spacing and has been tested at speeds up to 24.1 km/h (15 mph).

The RowSense system has been designed for maximum uptime. The kit includes two RowSense sensor assemblies with brackets (one for each front wheel). This design detects separate crop rows for better performance in poor crop stands. The paddles can be removed in less than 10 minutes for trailering or operating in other crops where RowSense is not compatible.

NOTE: It is recommended that RowSense sensor paddles should only be installed on the machine when operators are intending to use them for guidance. This should happen later in the crop stages when the crop rows are starting to shade over, making it harder to see the soil. This will help to ensure maximum crop safety.

For compatible John Deere sprayers, different sensor brackets are available to support varying row widths. The brackets are mounted within the wheel to help protect them in challenging terrain.

- Original sensor bracket (AKK19252) supports 76.2-cm (30-in.) row spacing

- Revised adjustable sensor brackets (KK66131 and KK63782) are available to support row spacing from 50.8 to 76.2-cm (20 to 30-in.). These brackets can be ordered through Service Parts for producers operating in narrower row spacing.

- Extension bracket kit (BPF11507) orients the sensors 9.4 cm (3.7 in.) closer to the center of the machine to support row spacings from 76.2 to 101.6-cm (30 to 40-in.).

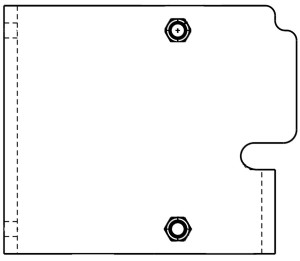

Original sensor bracket (AKK19252)

Original sensor bracket (AKK19252)

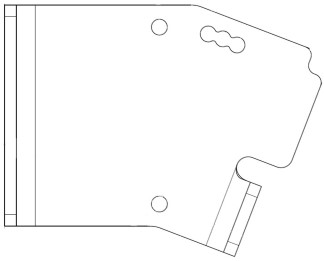

Adjustable sensor bracket (KK66131 and KK63782)

Adjustable sensor bracket (KK66131 and KK63782)

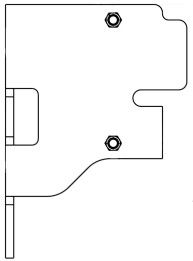

Extension bracket kit (BPF11507)

Extension bracket kit (BPF11507)

Hagie is a trademark of Hagie Manufacturing Company, LLC and similar to John Deere branded equipment, John Deere will also support Hagie equipment.