The 0 Series Round Baler family welcomes the first, John Deere, North-American built precutter. This feed system in front of these machines is the MegaWide HC2. The MegaWide Plus name is known as the industry-leading feed system since its introduction with the 7 Series Balers. John Deere continues that legacy with the 0 Series. Proven designs of the MegaWide were maintained and improvements were made to key components to gain significant capacity.

Features of the MegaWide HC2

The MegaWide™ HC2 will only be available in a precutter configuration (available on the 450M, 460M, 460R, 560M, and 560R models):

- 1.22-m (4-ft) wide machines will have 14 knives

- 1.52-m (5-ft) wide machines will have 20 knives

The MegaWide HC2 has the same 2.2-m (7.22-ft) MegaWide Plus pickup from the 9 Series. Dry hay and silage 0 Series configurations will also have the MegaWide Plus pickup.

Before the introduction of the MegaWide HC2 , the cam-clutch protection for the driveline was only available on the 9 Series Premium Balers. It is in the base for the MegaWide HC2 precutter configurations. This driveline pushes the limitations of the baler and the MegaWide HC2 system by offering the best machine protection John Deere can provide.

Another feature brought over from the 9 Series Premium Balers and being offered on the 0 Series is the grease banks. All daily greasing can be done from the ground in one central location.

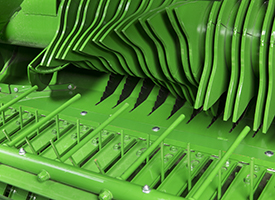

MegaWide HC2 roller baffle and MegaWide Plus roller baffles

MegaWide HC2 roller baffle and MegaWide Plus roller baffles

The roller baffle on the MegaWide HC2 doubled in size from the MegaWide Plus from 10.2-cm (4-in.) to 20.3-cm (8-in.) diameter to allow for increased speeds and performance in larger windrows.

The 450M, 460M, 460R, 560M, and 560R Balers that can be configured with the MegaWide HC2 feed system will have the same flare-to-flare pickup width of 2.2 m (7.21 ft). This 2.2-m (7.21-ft), flare-to-flare, width on 1.22-m (4-ft) balers is only a feature of the MegaWide HC2 feed system.

Primary rotor relationship to knives – front position

Primary rotor relationship to knives – front position

Primary rotor from bale chamber

Primary rotor from bale chamber

The primary rotor is only available on the MegaWide HC2 and is located directly behind the MegaWide pickups.

- This rotor grabs the crop and drags it over the knives to size the crop to a theoretical length size of 66 mm (2.5 in.)

- For the 1.22-m (4-ft) machines, there are 14 slots to receive the knives that are located on the floor of the feed system

- The 1.52-m (5-ft) machine has 20 knives and 20 slots

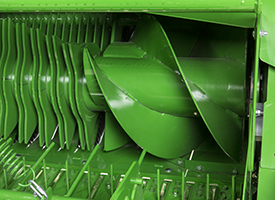

Fast-pitch augers on the primary rotor

Fast-pitch augers on the primary rotor

Industry-exclusive, fast-pitch augers have been placed on the primary rotor to move dry hay and silage past the transition points to avoid plugging.

MegaWide HC2 secondary rotor from bale chamber

MegaWide HC2 secondary rotor from bale chamber

The secondary rotor is another component on the feed system that was re-designed from the MegaWide Plus feed system to handle the increased demands of the high-capacity system.

- The secondary rotor in the MegaWide HC2 is similar in location and design as the MegaWide Plus spiral rotor.

- The hex shaft on secondary rotor rotor on the MegaWide HC2 was increased from 3.2 cm (1.25 in.) from the MegaWide Plus to 3.8 cm (1.5 in.)

- The diameter of the tube was increased for additional strength and to prevent silage wrapping

- The number of tines was increased from two to three for additional capacity and flow of crop into the starter roll and chamber.

A third drive roll is another feature that will only be offered with the MegaWide HC2 feed system.

- Precutting crop releases additional moisture into the feed system of the baler so the MegaWide HC2 feed system added a third drive roll on the number 11 roller to ensure trouble-free bale formation even in the most difficult, high-moisture silage conditions.

- This feature is available only on the MegaWide HC2 feed system

Drop floor – if the baler exceeds capacity and plugs, the MegaWide HC2 can lower the knife floor from the cab of the tractor to easily feed the plug into the chamber.

- Drop floor is an insurance policy to allow the operator to push the machine knowing that a plug can clear in 30 seconds, not 30 minutes.

- In factory-observed testing with the 2016 test fleet, 99 percent of the plugs were cleared from the cab.

- Floor is self-cleaning – when lowered to feed a plug, it allows chaff that has been built up around the knives to fall through into the windrow.

- This release of crop allows the feed system to stay cleaner

- Allows for easier engagement of the knives and servicing of the knives

- The floor is also responsible for engaging the knives

- Based on lack of success for re-engaging knives in competitive machines, John Deere made sure the MegaWide™ HC2 was built to meet the demands a Deere producer expects.

- Knife-engagement forces on the MegaWide™ HC2 are 10 times that of the New Holland™ Roll-Belt™ 460 CropCutter® Baler. It gives the producer the confidence that if the knives are engaged, they are all up and cutting.

- Once the knives are up, each knife has individual spring protection, limiting bent or broken knives.

- Hit a rock and the knife moves out of the way and automatically re-engages.

All MegaWide HC2 feed systems will have silage components to limit maintenance and prevent crop build up on belts.

- Driven auger

- Starter roll scraper knife

- Auxiliary take up roller

- For precutter machines only - external belt guides

- External belt guides were designed to dramatically reduce amount of chaff in the gate

- Available through parts – retrofittable through 7 Series balers

Descriptive model numbering system

All 0 Series Balers use alpha-numeric identifiers for the model names:

The MegaWide HC2 can be ordered on mid specification (M) and premium specification (R) balers.

R specification balers will have the premium pickup with improved internal components that are covered under the 2-year/12,000-bale premium warranty

M specification balers and pickups will not contain premium baler components – exception for this is the MegaWide HC2 feed system will have the premium cam clutch for the driveline and grease banks.

For more information about the model specifications, see the chart below:

| Baler option |

Applicable models |

E = Economy

|

440E and 450E |

M = Standard

|

450M, 460M,

550M*, and 560M |

R = Premium

|

460R and 560R |

*NOTE: The 550M is only available in dry hay and silage configurations.

New Holland, Roll-Belt, and CropCutter are trademarks of CNH Global N.V. and its subsidiaries.

Increased torque – the MegaWide HC2 feed system required an additional drive configuration to power the primary rotor and to meet the capacity goals.

- The MegaWide HC2 feed system has a T gearbox where the MegaWide Plus has a 90 degree box.

- The MegaWide Plus system had a cut-out clutch that protected the spiral rotor and pickup.

- The MegaWide HC2 eliminated that clutch because the secondary rotor is more robust than the MegaWide Plus spiral rotor.

- This allowed the primary and secondary rotor to be driven directly from the driveline.

- Both components are still clutch protected from the main driveline cam clutch, but there is approximately 10 times more torque being put through the primary and secondary rotor than what is found on the MegaWide Plus spiral rotor.

- This exponential change in torque is the driving force of the capacity gains in the MegaWide HC2 feed system.

- MegaWide HC2 pickup is still clutched for extended pickup life. That clutch is now located on the left-hand side of the baler. MegaWide Plus pickup clutches are still located on the right-hand side of the baler.

MegaWide HC2 feed systems will not have the adjustable crank handle for the pickup.

- MegaWide Plus machines will continue to have this an option.