ExactRate pump assembly at rear of 16-row 1725C

ExactRate pump assembly at rear of 16-row 1725C

The ExactRate liquid fertilizer system is a factory-installed solution that provides you with accurate nutrient placement during planting. Previously, you would have to deal with the inconvenience of cumbersome aftermarket systems for a hydraulically driven variable-rate solution. With ExactRate, John Deere delivers a complete planting solution for liquid fertilizer users. You can choose between in-furrow or offset delivery methods. A high-rate option without openers is also offered from the factory. This system delivers:

- Up to 20 percent more accurate nutrient placement in a turn compared to a non-turn compensating system

- 1 to 12 percent (4.3 percent on average) reduction in inputs through row-by-row section control

- Ability to run up to 16.1 km/h (10 mph)

- Closed-loop speed and rate change compensation

- Full integration into the G5 Universal Display

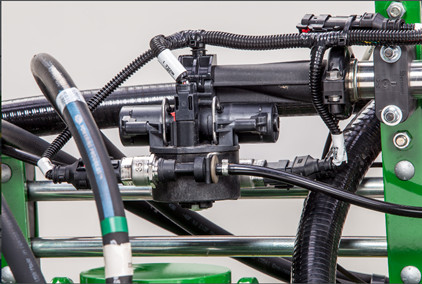

ExactRate nozzle body

ExactRate nozzle body

The ExactRate liquid fertilizer system is designed to take full advantage of the capabilities of ExactEmerge™ and MaxEmerge™ 5e planters. This factory-installed liquid fertilizer system delivers the same value as your electric drive planter including working at speeds faster than the traditional 8.05 km/h (5 mph), turn compensation, and row-by-row section control, all while accurately compensating for varying rates and speed changes. Additional features include row-by-row flow detection, as-applied documentation, and variable-rate capabilities.

Fertilizer flows from the tank to the pump, through a strainer and boom isolation valve, through a central flowmeter, and out to each nozzle body and row-unit for accurate delivery. The system is closed loop, meaning the pump and nozzle body duty cycle both adjust based on feedback received from the pressure sensor and central flowmeter. This design helps maintain an accurate application rate.

NOTE: ExactRate is not recommended for products that require agitation to maintain suspension.

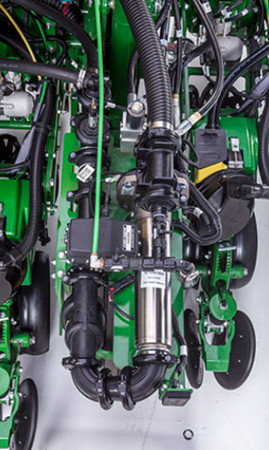

Pump

Pump assembly at rear of planter

Pump assembly at rear of planter

Instead of a tire-contact drive, a hydraulically driven centrifugal pump eliminates chain and sprocket adjustments to provide more speed flexibility over the entire rate range. This pump allows for a wide range of rate capabilities as well as strong durability. The wet seal design helps protect the pump if it is accidentally run dry for a short time.

Strainer

A strainer helps collect suspended particles and prevent them from causing blockages in the distribution system and nozzle bodies.

Boom isolation valve

The valve prevents the tank from draining out if there is a leak in the distribution system. If the pump is on, the valve opens to allow flow. When the pump is off, the valve closes.

Central flowmeter and pump pressure sensor

The central flowmeter and pump pressure sensor provide the rate control system feedback on flow and pressure to ensure an accurate application rate across the entire planter width. The flowmeter also supplies the as-applied rate data.

Distribution system and nozzle body

Distribution system and nozzle bodies routed on the wing of a 12-row 1775NT

Distribution system and nozzle bodies routed on the wing of a 12-row 1775NT

The 2.5-cm (1-in.) stainless-steel distribution lines not only reduce corrosion, but they also provide a clean integrated look. The distribution system is pressure tested at the factory to reduce the risk of leaks.

John Deere has leveraged ExactApply™ technology and capabilities from the sprayers to enable row-by-row section control and turn compensation that matches the high-performance planters. With ExactRate, there are no orifice changes for rate or speed adjustments, saving you time and effort while limiting exposure to product. Pulse-width modulation technology varies duty cycle (opening and closing of the valve) in the nozzle bodies in conjunction with flow and pressure measured from central flowmeter and pressure sensor controlling the system pump. The ExactRate liquid fertilizer system uses one nozzle body for two rows, limiting the number of parts and complexity on each machine. While you’re in the cab, you can keep an eye on each row with flow detection integrated into the Gen 5 display. The system warns you if it detects a variance in an individual row’s flow. A pressure sensor integrated into the nozzle body will detect a flow reduction or overapplication on the row.

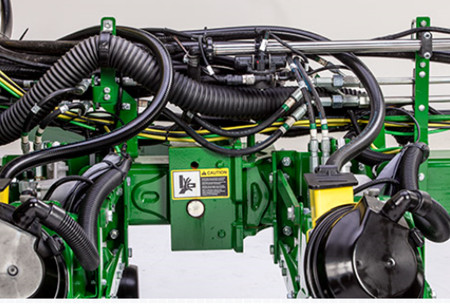

Keypad at rear of planter

Keypad at rear of planter

Just like on the sprayers, the keypad at the rear of the machine lets you conveniently perform a nozzle flow check to ensure product is coming out of each row before going to the field.

Rate Controller

The ExactRate liquid fertilizer system is compatible with the John Deere Rate Controller 2000 and GreenStar™ Rate Controller if a producer wants to apply a second product using a separate distribution system.

Direct injection

The ExactRate liquid fertilizer system does not have direct injection capabilities on the product being applied. If direct injection is needed on the secondary product, an additional rate controller is required.

NOTE: ExactRate system and John Deere Rate Controller 2000 with Raven ICD Direct Injection system is supported. ExactRate system and GreenStar Rate Controller with Raven ISO Direct Injection system is not supported.

ExactRate app on G5 Display

Easily adjust target rate and speed without leaving your seat. With turn compensation, inner and outer rates are automatically adjusted to maintain consistent application across the full width of the planter. This ultimately reduces the risk of seed burn by over application (turn compensations require a global positioning system [GPS] receiver). Another helpful feature is row-by-row section control for reduced overlap on headlands and waterways. G5 Documentation creates as-applied maps showing what product was applied where, providing accurate record-keeping.